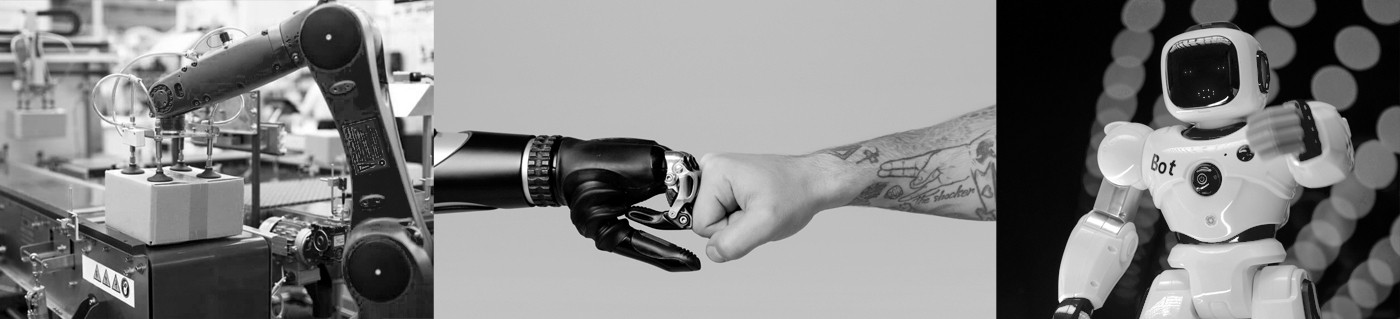

We are creating robots that can solve your problem as well as diagnose it. We will Give automation on industry and we've robots to solve industry issues. We would work as a consultancy providing solutions for the SMEs and MSMEs.

We provide customized robotic solutions with the help of industrial robots that perform a variety of tasks.

These robots are robust and make use of high tech systems. At the same time, they are affordable. We provide more than a solitary robot which gives an end to end solution taking care of your interests. Our 360° service range extends from exhaustive advance testing to robot maintenance and servicing. We develop proprietary control software and build component-specific tools and work holding systems. The field of industrial robotics may be more practically defined as the study, design and use of robot systems for manufacturing.

Our robotics are your go to partner for all necessities with the help of tailor made solutions.

Our team of engineers will assist you in creating a deep and extensive experience in various fields of robotics applications to help your company thrive and make good use of all the robotics technologies.

In some areas, we also act as an advisor providing you guidance on quality of technology as a general contractor and integrator. We build component specific tools for your robots coordinating system vendors to create workholding systems for your robot.

We will supply solutions tailored to your specific needs instead of one-size-fits-all products.

Our engineers are highly skilled and experienced in industries as wide-ranging as:

Metal (e.g. automotive)

Paper

Plastics

Glass

Logistics

Food

We provide AI based solutions for industry robots. Make the work easy and automate your production with faster result.